Plant Data

Overview

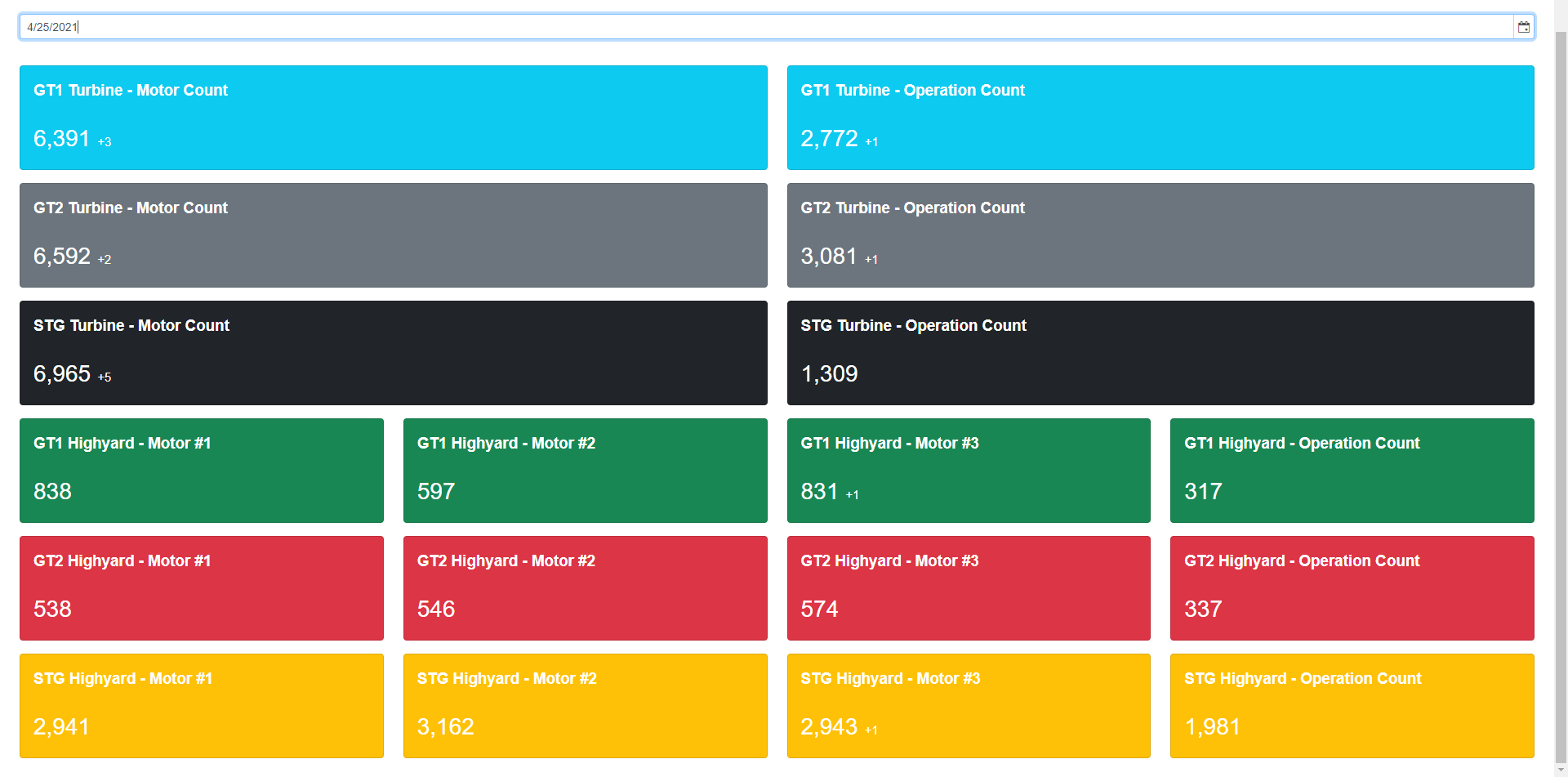

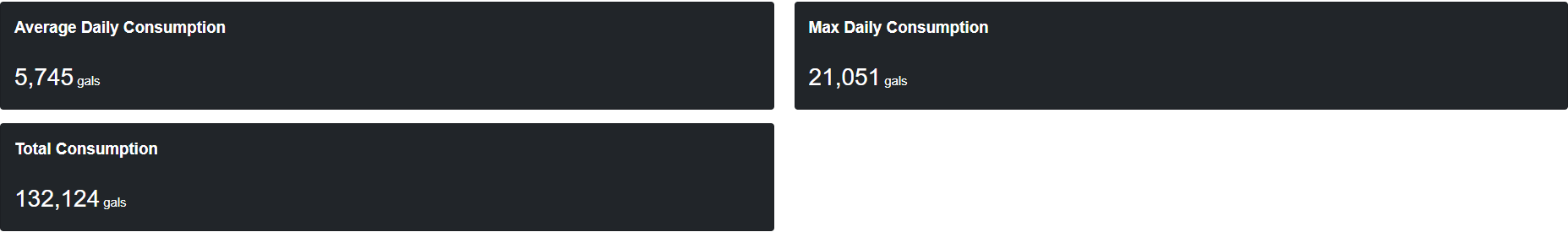

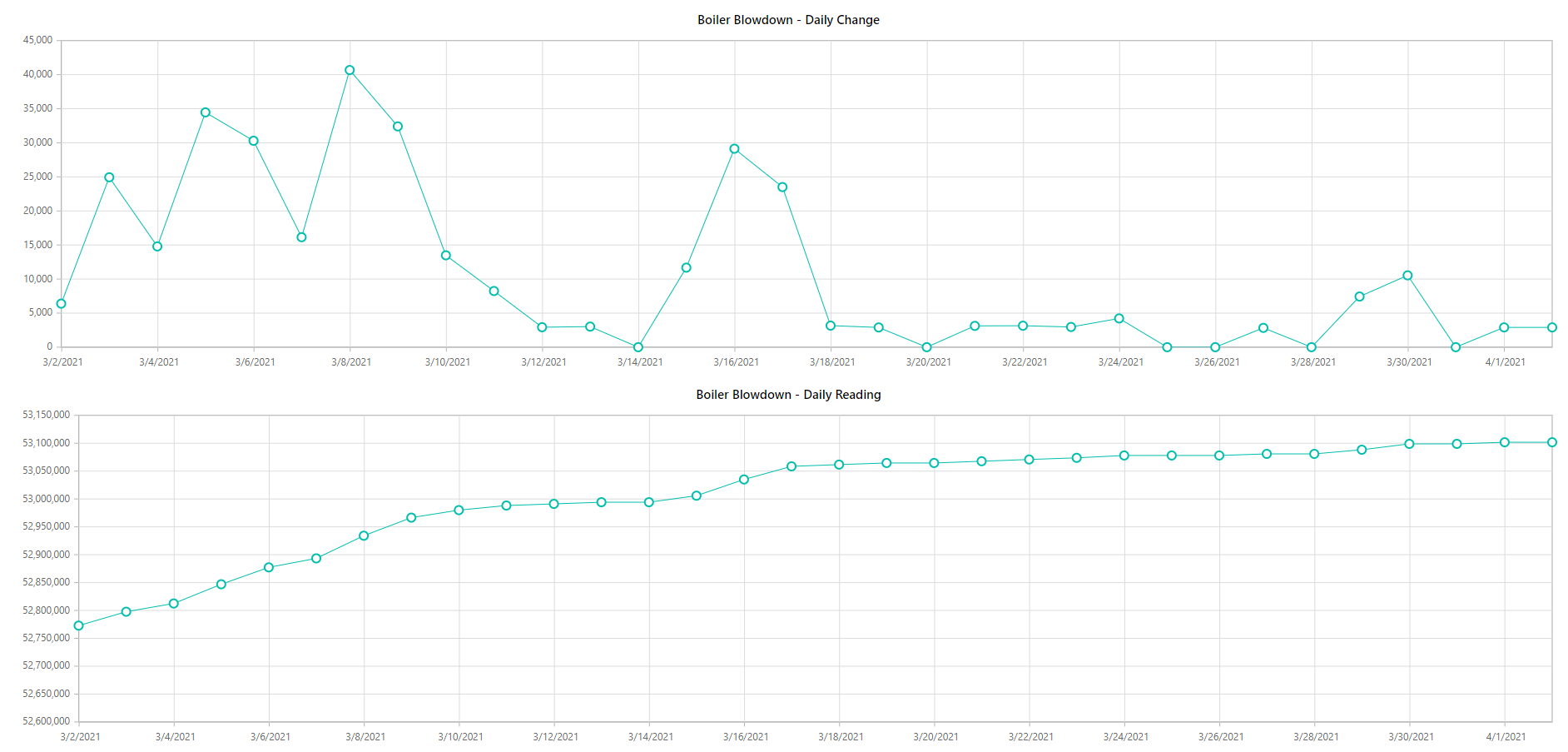

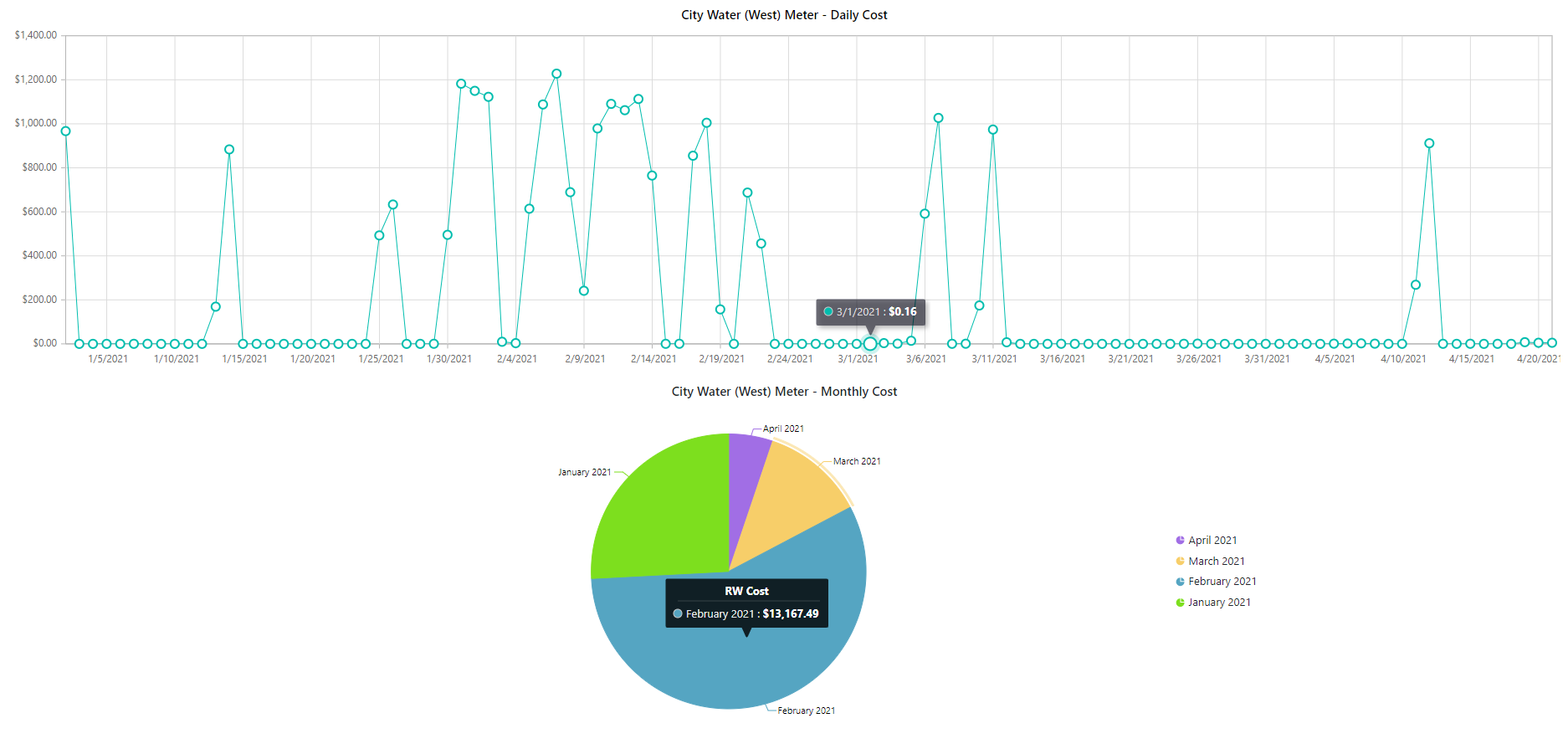

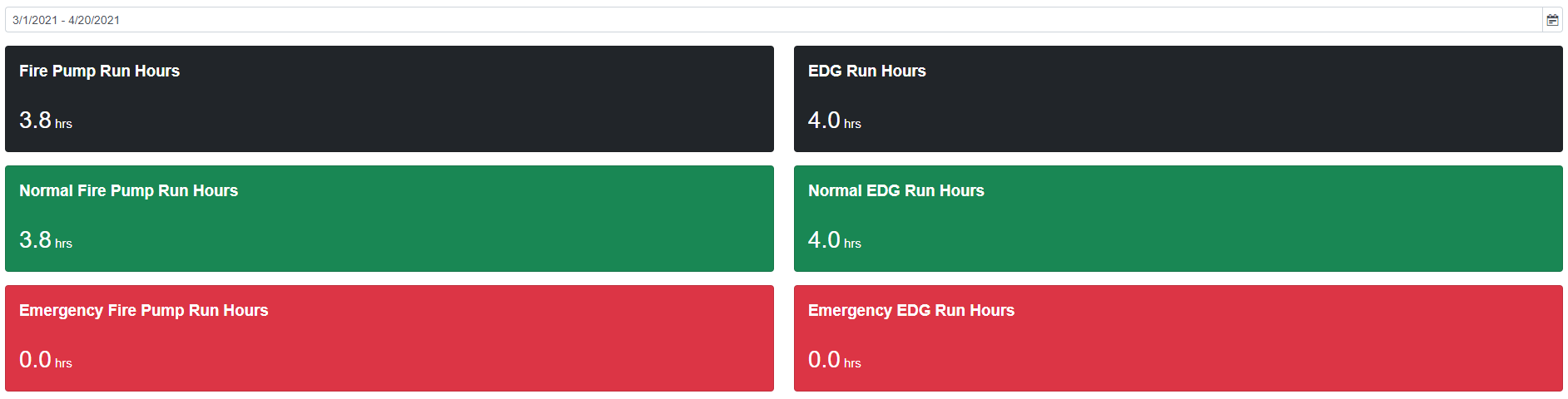

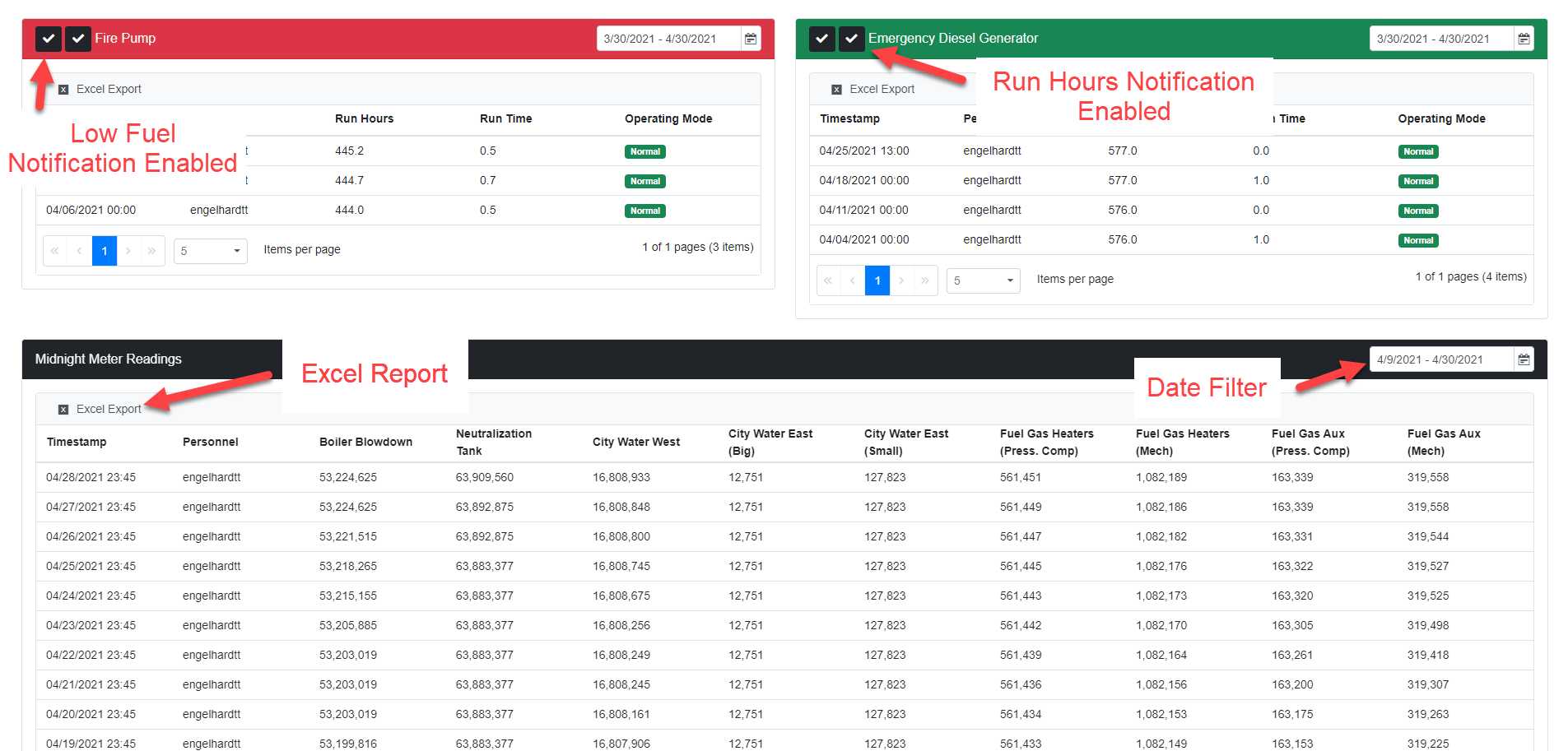

Plant Data is a comprehensive application designed to centralize and streamline plant data collection, monitoring, and reporting. It aggregates multiple data sources—including manual meter readings, internal combustion runtime, breaker operation counts, plant orientation logs, and fuel levels—into a single, user-friendly interface. The application leverages AVEVA PI System’s Asset Framework and notifications to automate data validation and alerting, ensuring that missing or erroneous data is quickly identified and addressed.

Previously, critical data such as meter readings and runtime hours were tracked in spreadsheets, leading to frequent errors and missed entries. Plant Data resolves these issues by sending proactive notifications when readings are missing or appear incorrect, and by automating fuel level monitoring and alerting. The system also simplifies the process of tracking breaker status changes and provides historical views for easier troubleshooting and reporting.

For contractor orientation logs, Plant Data integrates with the plant logging system’s database, parsing complex schemas to enable efficient searches by company, personnel, or date—capabilities that were previously unavailable.

Goals

- Centralize Data Access: Provide a single location to view and manage data from multiple plant sources.

- Proactive Data Quality: Highlight missing or erroneous data and send notifications to ensure timely corrections.

- Streamline Reporting: Make data easily accessible and reliable for use in operational and compliance reports.

- Simplify Orientation Tracking: Enable efficient searches and reporting for contractor orientations without duplicating data.

Challenges

- Data Quality & Reporting: Developing best practices to ensure data accuracy and repeatable, reliable reports required close coordination with plant management and iterative process improvements.

- Complex Schema Integration: Parsing and filtering data from third-party plant logging systems with complex, inflexible schemas demanded custom logic to efficiently extract and present the required information.

- Change Management: Transitioning from manual, spreadsheet-based processes to an automated, proactive system required user training and updates to standard operating procedures.